Text|Pan Xiaoyu, Shen Guangli

Editor|Peng Xiaoqiu

36氪 was informed that the robot “hand-eye” product provider “Ruben Technology” has recently received tens of millions of A+ rounds of financing. This round of financing was invested by Amber Capital and CRRC Times. This round of financing will be mainly used for product research and development, talent development and marketing.

In recent years, with the rapid development of intelligent manufacturing, the trend of “machines helping people” in my country is obvious, and 3D vision sensors and industrial robots have considerable development space. As segmented industry applications begin to land, the demand for intelligent workstations combining vision and robotics is also greatly increasing.

Based on this, Ruben Technology, established in 2018, focuses on the research and development of 3D vision products and smart hand-eye workstations, and has achieved remarkable results in core technical fields such as visual calibration, dynamic structured light, and robot motion planning. At present, its products RVC 3D camera, VDA visual displacement analyzer, and smart hand-eye workstation have been implemented in the fields of automobile, consumer electronics, heavy industry, footwear, industrial testing, logistics and other fields.

Such as this technology product

Specifically, the products of this technology mainly cover three aspects:

One is the RVC 3D industrial camera. Through modular design, this series of products is suitable for various scenarios such as quality inspection, welding, grabbing, spraying, grinding, depalletizing and so on. The RVC 3D industrial camera series, also known as the universal standard camera by this technology, adopts active dynamic structured light technology. In terms of performance, it can reach micron-level point cloud accuracy, up to a field of view of 3.5 meters, and has high stability and IP65 high protection performance.

The second is the Visual Displacement Analyzer (VDA), which is mainly oriented to the needs of spatial displacement monitoring and analysis in the fields of engineering, materials, municipal administration, and transportation, including wind tunnel experiments, shaking table experiments, load experiments, rail monitoring and maintenance, bridge building health status, ancient Building restoration and other scenes. VDA can monitor and analyze 2D and 3D topography, displacement, deformation, strain, vibration, speed, acceleration and other information at high speed and high precision by using computer vision technology to analyze continuous multi-frame pictures.

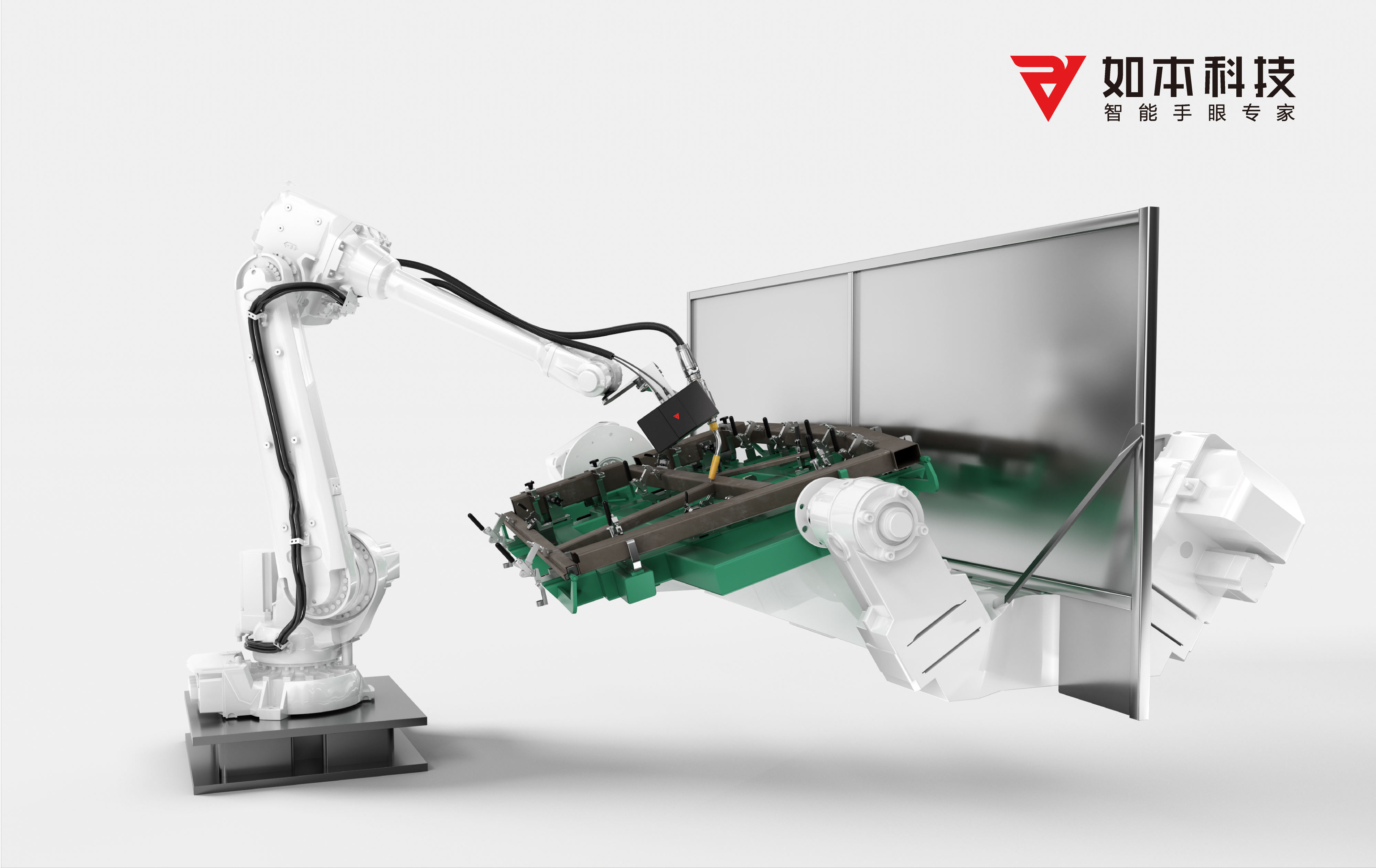

The third is the smart hand-eye workstation. Based on robot motion planning and 3D vision technology, the intelligent hand-eye workstation built for vertical industry standard processes can promote and solve the flexibility problem of multiple varieties and small batches. At present, it has been implemented in scenes such as cutting, welding, spraying, and dispensing of car body windows in the fields of subway, high-speed rail, and passenger cars.

In terms of team, for example, the core team of this technology mainly comes from Tsinghua University, Harbin Institute of Technology, etc., with more than 10 years of experience in the fields of structural optics, visual algorithms, and motion control.

“Hand and Eye” Products

With the rapid expansion of the downstream market of the 3D vision industry, the subdivided and complex sensing requirements between different processes are becoming the industry theme. As far as the process of shoe-making gluing is concerned, there are different spraying methods for different SKUs, which require high precision, uniformity, and fast line changing rhythm. In addition, for the existing robot programming, drag-and-drop programming still has certain constraints. The operation of lowering the threshold often sounds more story-like, but it is full of inflexibility in practical applications.

There are more and more 3D vision manufacturers, and most of the robot application industries involve non-standard customized products. For example, what is the idea of this technology? With the above questions, we also chatted with Li Hui, the founder of Ruben Technology:

36氪: Why does Ruben Technology carry out the “hand-eye” scene at the same time?

Li Hui: Ruben has two meanings. The first level is to obey people’s original heart, and the second level is to obey people’s nature. It also corresponds to our original intention of starting a business, which is to solve the damage caused by harmful duplication of labor, so our ultimate goal is actually to solve the problem of people, not the problem of a single eye or hand.

36氪: Accuracy, speed, stability, etc., which are the existing competitive dimensions of 3D cameras? What is the uniqueness of Ruben technology?

Li Hui: Different process requirements in vertical industries will put forward some different specifications for 3D cameras. Therefore, at this stage, 3D vision products are mostly used in which industries, and what kind of competitive characteristics they have. With the opening of downstream subdivision industries, a large number of different 3D cameras will appear, so the competition of 3D cameras does not exist in a single dimension such as accuracy and size. It is the company that is closer to the customer and better able to turn demand into an effective product, the more competitive it is.

Our RVC 3D series 3D cameras have more than ten 3D camera products in the capture, inspection, and process processing scenarios. In the future, we will follow this principle to launch more products to serve vertical industry customers.

36氪: Why establish a VDA product line? From indoor detection to outdoor monitoring products, what kind of problems are faced?

Li Hui: The VDA product line originated from the fact that the demand side first found us in 2019, and because spatial displacement analysis and monitoring are very important for scenarios such as railway track warranty and building inspection, we built this product based on our own visual technology accumulation. Wire.

Indoor 3D vision calibration is relatively easy, but it is difficult to calibrate something 50 meters away outdoors, and there is no way to directly reuse indoor technical experience. In addition, in engineering monitoring, there will be changes in light and occlusion of people coming and going, which involves a lot of image feature extraction work, so we need to develop some new outdoor calibration methods to solve it.

36氪: What are the technical difficulties involved in realizing the flexible motion planning of robots?

Li Hui: Before a robot moves, it needs to generate motion through motion planning, which is similar to the role of a traditional robot brain. The movement of the robot can be simply regarded as several axis movements, but in fact it is a search problem in a high-dimensional space. Because there are obstacles in the environment and the robotic arm itself has limitations, this movement is to find an optimal path to the destination in a limited space. When this high-dimensional space becomes six-dimensional or even higher, the search becomes more difficult, so a lot of algorithms will be derived, so it can only be realized with rich accumulation in algorithms.

36氪: How does Ruben realize flexible motion trajectory control?

Li Hui: We have been exploring and accumulating motion planning algorithms. The current mainstream is to use and deploy robots through instruction programming or drag-and-drop teaching, which is not conducive to solving the flexible needs of small batches and multiple varieties. We add an abstract instruction before the user learns, such as inputting the motion speed from point a to point b, and calculate the motion trajectory planning inside and the rotation of the axis. It can deeply adapt to different types of robotic arms because the instructions we send to the robot are not instructive languages, but continuous axis rotation instructions, which directly control the axis to achieve precise control.

36氪: How do you predict the future trend of the 3D vision industry?

Li Hui: 3D vision can be divided into two parts: 3D sensor and upper-layer application algorithm. Ultimately, it still needs to serve high-quality and cost-effective solutions to specific industry problems. In order to better solve different problems, the data that needs to be acquired by sensors will also be different, and the processing algorithms of the upper layer will also vary widely. I believe that a large number of 3D sensor products will appear in the future, and the application algorithm layer will be more open, and more talents from different industries will flow in.

I think our industry still needs to focus on different scenarios, and we can’t talk about technology, products but not scenarios. Instead, focus on a certain scene and form a certain channel and ability, and then start to expand the scene and process route.

media coverage

36Kr investment community start-up state

Related events

- Ruben Technology completed tens of millions of yuan in A+ round of financing2022-10-14

- Lingxi Robot has received hundreds of millions of B+ rounds of financing2022-07-22

- Robot 3D vision manufacturer Elson completes tens of millions of yuan in Series A financing2022-07-12

- Xingyuanzhe Technology completed nearly 40 million US dollars in B+ round of financing2022-06-20

- Yishi Technology completed the A round and A+ round financing of over 100 million yuan2022-03-29

This article is reprinted from: https://readhub.cn/topic/8k69kj0cLE2

This site is for inclusion only, and the copyright belongs to the original author.