Lithium iron phosphate battery LFP , nickel-cobalt-manganese ternary battery NCM , nickel-cobalt-aluminum ternary battery NCA .

The three are three large-scale commercial power batteries currently carried on electric (hybrid) vehicles, and these three power batteries basically account for the vast majority of new energy vehicles installed in the world.

First of all, from the perspective of energy density, the country’s industry-leading development goals are obviously planned according to the improvement of energy density.

In 2020, the energy density of a single cell will reach 350Wh/Kg, in 2025, the energy density of a single cell will reach 400Wh/Kg, and in 2030, it will reach 500Wh/Kg.

The upper limit of system energy density of lithium iron phosphate battery (LFP) is 200wh/kg, while the upper limit of system energy density of ternary lithium battery (NCM/NCA) is 350wh/kg. It can be seen that the energy density of lithium iron phosphate batteries is far less than that of ternary lithium batteries, which also means that for battery life, lithium iron phosphate batteries are much weaker than ternary lithium batteries.

Therefore, NCM and NCA have been sought after by the market in the past few years. The energy density of NCA batteries used by Tesla in the early days is more than twice that of BYD LFP batteries.

Here is a brief description of NCM and NCA.

The most common ternary lithium battery in China is NCM, which is directly related to NCA’s strict technical requirements and high threshold (patents are basically in the hands of Japan and South Korea).

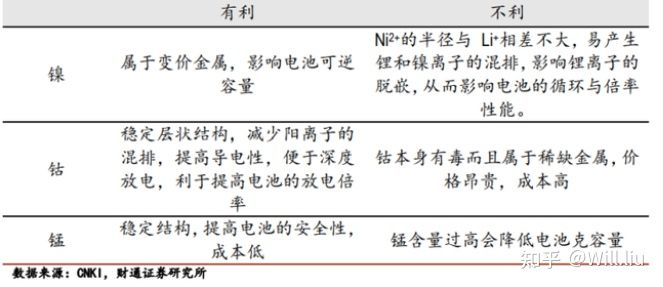

NCM, an acronym for Nickel Cobalt Manganese, where each element has its own unique role.

The advantages of high-nickel batteries are obvious, that is, while reducing costs (less cobalt), they can also increase battery energy density (more nickel). However, the disadvantages are also very prominent, that is, less cobalt and more nickel, resulting in poor stability of the layered structure, easy decomposition of the electrolyte and side reactions between the electrolyte and the surface of the material, resulting in by-products that lead to changes in interface conductivity. Difference.

In general, the current high-nickel, low-cobalt, and low-manganese solution improves the energy density (increasing battery life) with a low-cost solution, but in exchange for a decrease in cycle life, safety, and thermal stability .

And NCA is actually similar to the ratio of high nickel battery 811, the common ratio of NCA is 8:1.5:0.5. In the NCA production process, aluminum is an amphoteric metal and is not easy to precipitate. Correspondingly, the tightness requirements of the production equipment are high, the temperature and humidity requirements are stricter than NCM, and the humidity requirements are controlled below 10% (LiNiO2 in NCA is easy to absorb moisture), which increases the technical requirements and production costs accordingly. That is, there is a serious side reaction in the charging and discharging process to generate gas, which will cause the battery to bulge and deform easily, causing potential safety hazards. Therefore, NCA adopts a cylindrical battery case that is more resistant to internal pressure. In addition, the disadvantages of high-nickel NCM batteries are the same as high-nickel NCA, which increases energy density and reduces thermal stability.

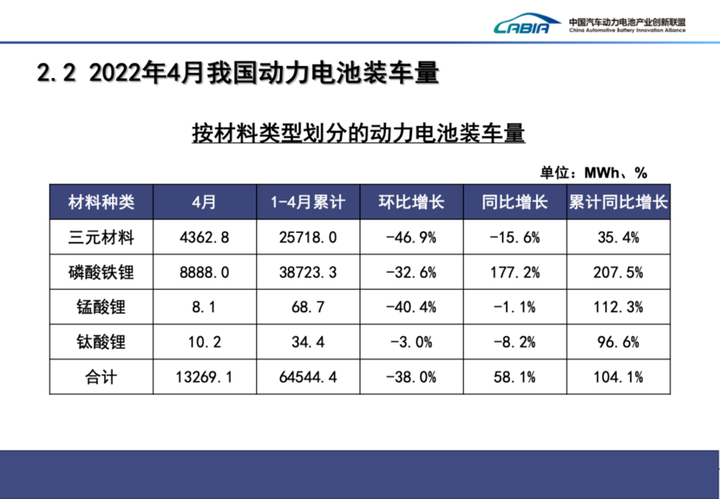

However, starting from 2021, the domestic power battery loading and production have completely turned in a different direction, and the short-life lithium iron phosphate has greatly surpassed the long-life ternary lithium battery. In 2021, the output of ternary batteries will be 93.9GWh, accounting for 42.7% of the total output, a year-on-year increase of 93.6%; the output of lithium iron phosphate batteries will reach an unprecedented 125.4GWh, accounting for 57.1% of the total output, a year-on-year increase of 263%. In December 2021, the output of ternary batteries was 11.4GWh, while the output of lithium iron phosphate batteries was 20GWh, almost twice that of ternary batteries.

Therefore, judging from the current choices in the domestic market, lithium iron phosphate batteries with weak energy density have become the first choice of domestic car companies.

From January to April 2022, the loading volume of lithium iron phosphate has thrown the ternary lithium battery out of sight. The loading volume of lithium iron phosphate batteries in April 2022 is more than double that of ternary materials.

My previous answer also said a lot of safety analysis. The thermal stability of ternary batteries is poor, the thermal stability of lithium iron phosphate is strong, and the cycle life is long. Therefore, car companies adopt the solution of lithium iron phosphate batteries.

Indeed, when the temperature exceeds 180-200 degrees Celsius, the positive electrode of the ternary battery begins to decompose, and a large amount of oxygen is released. The oxidative reaction of oxygen with the solvent produces a large amount of gas (box bulge) and releases a large amount of heat (smoke). Once the chain reaction occurs, the huge heat cannot be dissipated. The explosion-proof membrane of the cell ruptured, and the flammable electrolyte was sprayed out. The above is the occurrence of the deflagration phenomenon of the ternary battery.

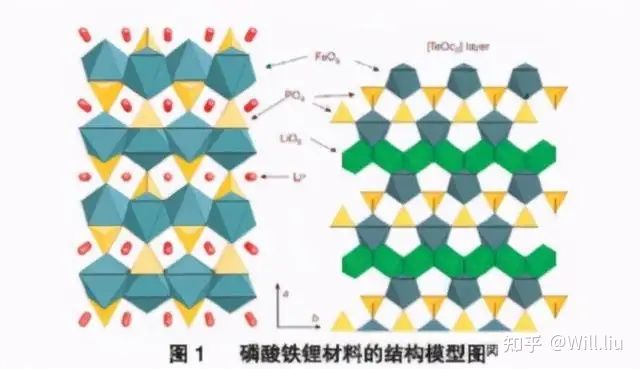

The olivine structure of lithium iron phosphate has extremely strong thermal stability, and the PO bond is stable and difficult to decompose.

Even at high temperature or overcharge, it will not collapse like ternary materials. Generally speaking, the lithium iron phosphate positive electrode will decompose when it reaches above 700-800 degrees Celsius, and it will produce a decomposition reaction and will not release a large amount of oxygen, so even in an ultra-high temperature (outside fire) environment, the lithium iron phosphate battery will not be violent. combustion. In various experiments in the laboratory, it has also been verified that under the experiments of acupuncture, extrusion, drop, thermal shock , impact, etc., at most, the lithium iron phosphate battery is seen smoking, and it is difficult to see the phenomenon of lithium iron phosphate burning.

However, from the perspective of enterprises, especially the special impact of the epidemic in the past three years and the follow-up, I think that car companies choose lithium iron phosphate batteries as the main choice, because cost considerations account for a larger factor.

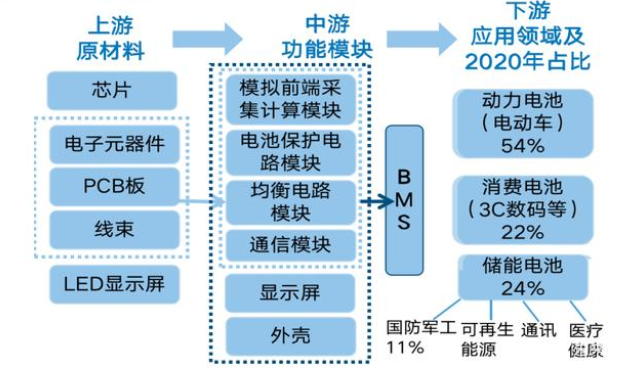

One is that the thermal stability of the battery itself is relatively strong, which also means that the thermal management requirements of the vehicle BMS are lower. Throughout the BMS industry chain, whether it is software design or hardware chips, cost-effective solutions can be adopted. Even if the BMS management is relatively extensive, passive protection measures such as flame retardant and loss reduction can also ensure the safe use of lithium iron phosphate batteries during a long service life.

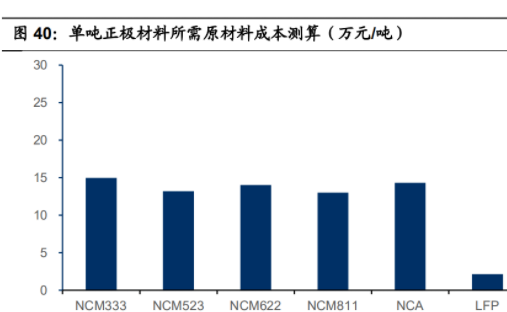

On the other hand, whether it is NCM’s high nickel and low cobalt version NCM811 or NCA, the price of cobalt is expensive, resulting in the cost of ternary lithium power battery is much higher than that of lithium iron phosphate battery (LFP).

All of the above, in the context of the country’s basic withdrawal of subsidies for high-density power batteries, the low-cost medium battery life plan has become the choice of most car companies during the epidemic. lose money.

But in the long run, whether from consumers or car companies, the curve of high energy density, low cost, and high safety must eventually find a suitable balance of the three. Therefore, with the maturity of the high-nickel solution, the improvement of BMS, and the reduction of cost pressure, the proportion of batteries in the ternary lithium series should gradually rise.

(Picture source network, invade and delete!)

References:

1. “ http://finance.sina.com.cn/stock/stockzmt/2021-04-16/doc-ikmxzfmk7248650.shtml “

2. ” https://www.pcauto.com.cn/hj/articl e/ 1291840.html “

Source: Zhihu www.zhihu.com

Author: Will.liu

[Zhihu Daily] The choice of tens of millions of users, to be a big cow of new things in the circle of friends.

click to download

There are 4 more answers to this question, see all.

Further reading:

Where can lithium battery be recycled?

This article is reproduced from: http://www.zhihu.com/question/438868135/answer/2514581238?utm_campaign=rss&utm_medium=rss&utm_source=rss&utm_content=title

This site is for inclusion only, and the copyright belongs to the original author.