Original link: https://codechina.org/2022/06/artisan/

Image by Martin Rehrl from Pixabay

Domestic woodworking videos generally prefer to render all by hand, while American woodworking is just a bunch of machine tools, which are efficient and reliable. Now the spirit of craftsmanship has been replaced by handwork. This largely comes from Japanese propaganda, and there are also many people in China who like to do so. Switzerland likes to do this too.

Swiss watches are so expensive and the market is so good, so it must be good for Swiss people to talk about craftsmanship and hand-made?

First, the fact that Swiss performance is so expensive is not because it is good. Precisely because it is not good enough. In the old days of mechanical watches, many countries in Switzerland and Europe made watches. Later, Switzerland took the lead and established some standards. At this time, Japan also participated in the watchmaking industry. Slowly, mechanical watches are also doing well, and they can even surpass some Swiss watches in competitions and win the championship.

This is actually a trivial matter. Later, various countries began to develop quartz watches. On December 25, 1969, Seiko Japan took the lead in producing the world’s first quartz watch, the Astron, which opened the quartz revolution. At the beginning, Swiss companies also developed quartz watches. In April 1970, Switzerland’s first quartz watch, the Ebauches SA Beta 21, was unveiled. Quartz watches are not cheap at first, but their performance far exceeds that of mechanical watches.

But in general, the Swiss watch industry rejected quartz technology and continued to produce mechanical watches. By 1978, the market share of quartz watches surpassed that of mechanical watches. In particular, with the rise of American and Japanese benchmark companies, the Swiss watchmaking industry stagnated and fell into what is known as the quartz crisis.

Many Swiss watch companies closed down, the industry was sluggish, and the number of employees plummeted. Between 1970 and 1983, the number of Swiss watchmakers fell from 1,600 to 600; from 1970 to 1988, the number of employees in the Swiss watch industry fell from 90,000 to 28,000 people.

In this crisis, the two major watch groups in Switzerland, ASUAG and SSIH, merged in March 1983 to form the predecessor of the Swatch Group, ASUAG/SSIH, hoping to save the Swiss watch industry. The Swatch Group)”

Swatch Group made a lot of money by selling cheap and low-cost Swatch watches. Swatch even specifically reduced the number of parts from 91 to 51 to facilitate mass production with machines and further reduce costs.

picture

Pictured is a Swatch watch for sale on Amazon

The Swatch Group has successfully acquired a large number of well-known Swiss brands. The following brands are owned by the Swatch Group:

- Swatch

- Balmain

- Blancpain

- Breguet

- Calvin Klein

- Certina

- Endura

- Flik Flak

- Glashütte-Original

- Hamilton

- Harry Winston

- Jaquet Droz

- Léon Hatot

- Longines

- Mido

- Omega

- Rado

- Tissot

However, even though the Swatch Group is quite successful, the Swiss watch industry in general is not prosperous enough, so including the famous brands under the Swatch Group, as well as other surviving Swiss watch companies Patek Philippe, Vacheron Constantin and Rolex, etc., the entire Switzerland The mechanical watch industry began to shift to the high-end luxury market. The mechanical watch became synonymous with luxury, and the Swiss watch industry was completely revived. (1)

So are they the best products made by craftsmanship? In fact, no, they are unable to beat the normal market, and can only retreat to the luxury market.

But, even if they are luxury goods, are Swiss watches really all handmade? Let’s take a look at what the watch industry has to say:

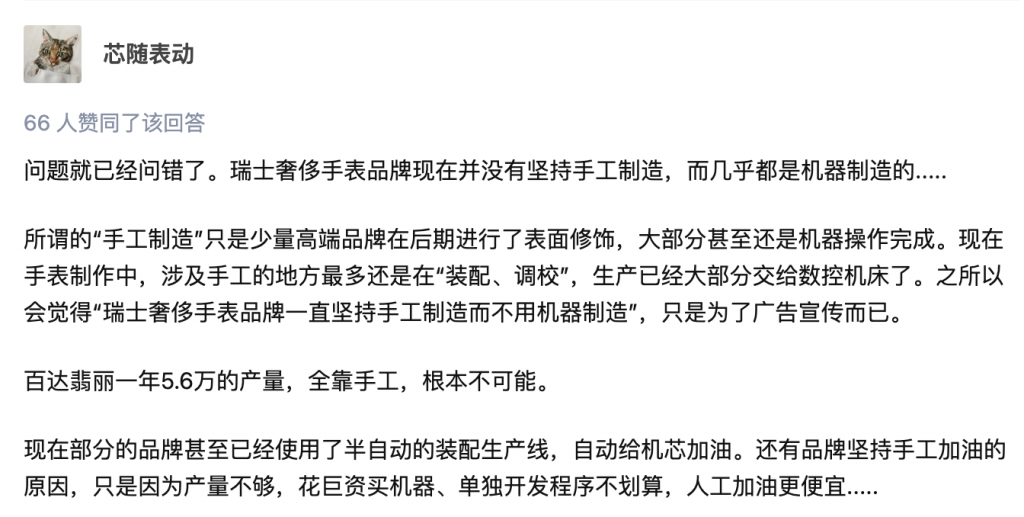

picture

This comes from the question “Why Swiss luxury watch brands have always insisted on hand-made instead of machine-made? “The answer that the lower core moves with the watch.

Now many people may understand why many luxury watches will tell you what hand-burning process is used for the dial, and so on.

It is not a real craftsman who blindly admires handicraft. When the technology was not developed in ancient times, ancient craftsmen also worked hard to develop various tools, pursuing efficiency, precision, and beauty, rather than something purely manual that satisfies the interests of small intellectuals. The primitive man made stone tools at first, and then used grinding stone tools, which is also a step-by-step progress. The same goes for craftsmen of all kinds.

For example, we know that the older the cultural relics, the more valuable they are. Ancient Chinese jade processing is very powerful. But some people have the illusion that some ancient jade products cannot be made now. It’s actually much easier and better quality with modern tools. To give the simplest example, many methods of identifying ancient jade are actually looking for technological characteristics. What is the process characteristic? In fact, it is the processing traces brought by different processing techniques, technologies and methods. For example, sometimes, it is the misalignment marks caused by the poor alignment accuracy of the drill. Some are irregular scratches caused by Jie Yusha, and so on. If it is processed with modern technology, if it is not purely for the purpose of counterfeiting, making it old, and deliberately using the tools and techniques of the past to do it, the processing will actually be more accurate. So sometimes the way of judging ancient jade is to see if it is made too finely, some ancient crafts with fineness are difficult to achieve, so it should be modern crafts.

Last time I watched a video of a Japanese seal master, and I liked it very much. Some people came to it, the master made the design seriously, and then turned on the CNC machine, and it was done in a few minutes. The people who went there said, are you not a master craftsman, why use a machine. The master said that it is better and faster to use machines, why not? This is the real craftsman, doing faster, better, and more beautiful is the pursuit, not how to do it in vain.

People who don’t understand will say, that all use cnc, is it just like the master that I do. In fact, it is not. All kinds of machine tools need to be adjusted, maintained and studied. There is also how to design to give full play to the advantages of a specific machine tool, and how to make process selection. These are unheard of for the uninitiated, but they are actually the coolest things in manufacturing.

For example, everyone will understand that lithography machines are not only available to TSMC, but other foreign manufacturers can also buy the same lithography machines. Why is the 5nm process developed by TSMC first? There are countless details in terms of technology. In some aspects, TSMC is the teacher of lithography machine manufacturer asml. Not everything is possible with a machine tool. The core is how you use the machine well. This means that you have a gun, you are not a sharpshooter, and marksmanship is also a knowledge.

For another example, is it all the same with 3D printing? Not really. Someone asked if 3D printing a screw is strong? This is the point of view of ordinary people. A great man, such as a certain youtube god, is to make the results of vertical printing, horizontal printing, and 45-degree oblique printing, and then actually test the strength and effect. Doing everything is the same, you need to study carefully…

Note 1: Lots of references, wikipedia Quartz Crisis entry https://zh.wikipedia.org/zh-cn/%E7%9F%B3%E8%8B%B1%E5%8D%B1%E6%9C%BA

This article is reprinted from: https://codechina.org/2022/06/artisan/

This site is for inclusion only, and the copyright belongs to the original author.