Today, I saw the record of the LONGi HPBC press conference posted by the golfer’s sketch on Snowball. Zhong Dong denied the statement that HPBC is a P-type IBC, and proposed that the official name of HPBC is “composite passivation back contact battery”. This article will do some discussions on the development of HPBC’s technical route, and point out the mistakes, please give more advice.

1. Questions about HPBC

At the press conference, HPBC released the performance indicators of 25% cell efficiency and 23% module efficiency, which is comparable to Jinko’s TOPCON cell efficiency, and even has a disadvantage compared to Aixu’s ABC cell efficiency of 25.5%. What about the grand release of HPBC as an epoch-making product? You know, LONGi has researched in TOPCON and HJT technology, and often refreshes the laboratory conversion efficiency records of HJT and TOPCON. It took LONGi 4 years to invest 1 billion to create a product that is not efficient in terms of efficiency, and it is also an epoch-making product. business logic.

Second, the bottleneck of the new battery

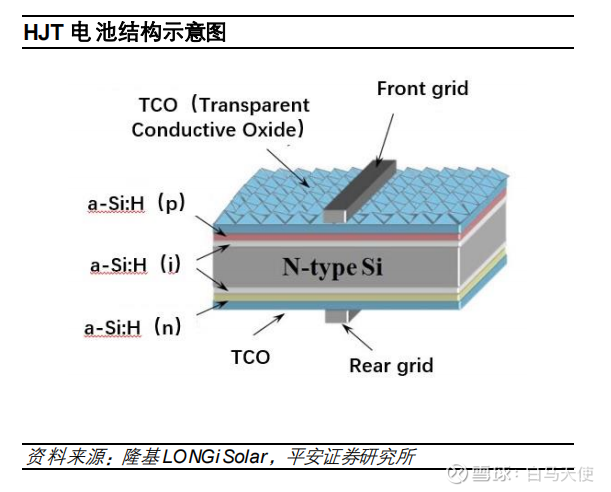

At present, a technical bottleneck of either TOPCON or HJT is the high silver consumption. The silver consumption per watt of both is higher than the current perc technology, so the silver-free technology will be a future core technology of the photovoltaic industry. I have stated in the article “The Bottleneck of Current Photovoltaic Cell Technology” that silver consumption is a major bottleneck restricting the development of photovoltaics, which is aimed at the photovoltaic industry as a whole. But in fact, for HJT battery technology, there is still a bottleneck, that is, the TCO layer of HJT battery, because the rare metal indium needs to be used in order to take into account both conductivity and transparency. Indium is a much rarer and more expensive material than silver. It can be used in laboratories with good efficiency. In fact, there is simply not enough indium production to support large-scale battery mass production, so first-tier manufacturers are choosing new battery technology routes. At times, HJT technology lines were not selected.

3. Understanding of HPBC

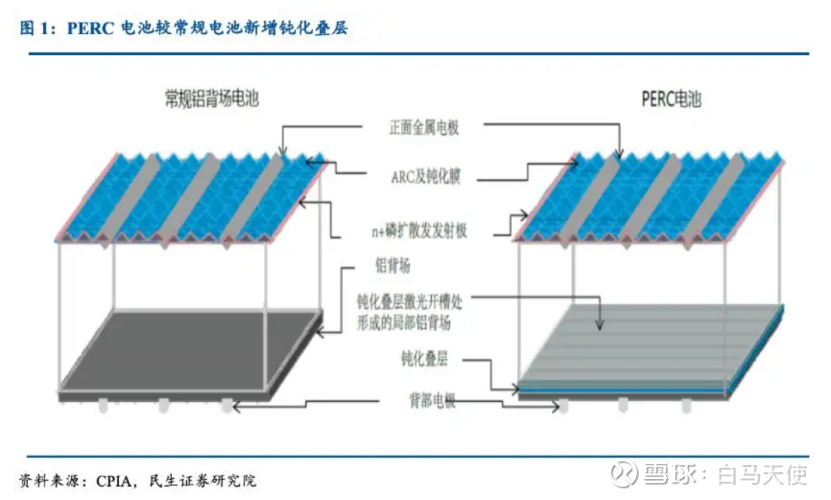

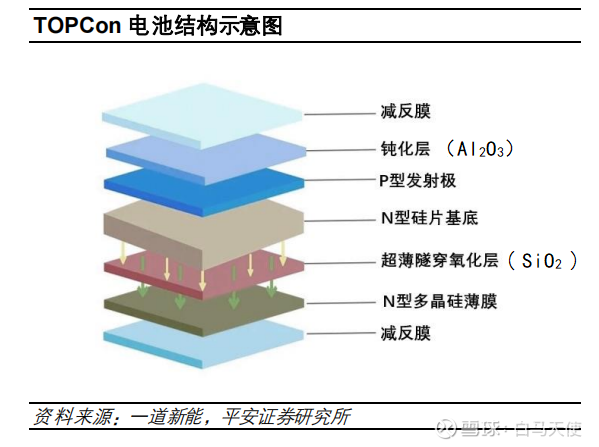

The emphasis on passivation in LONGi’s new battery is in line with the characteristics of battery technology development. In fact, one of the main directions for improving battery efficiency is the improvement of passivation technology. The core technology of PERC battery replacing all-aluminum back field battery is to add a passivation layer in front of the aluminum back field. TOPCON technology is more advanced than PERC in that the back passivation layer of PERC is perforated, while the back passivation layer of TOPCON does not need perforation, and the passivation effect is better. HJT even replaced the emitter stage with a passivation layer. It is precisely because the conductivity of the passivation layer is not good, so the HJT battery needs to add a layer of TCO on the passivation layer to enhance the conductivity.

From the point of view of passivation materials: PERE uses SiO2 on the front and Al2O3 on the back; TOPCON uses Al2O3 on the front and SiO2 on the back; HJT uses amorphous silicon (a-Si) on both the front and back. From the word “composite passivation”, it shows that although HPBC currently uses P-type PERC + back contact technology, this combination is not fixed, and other battery technologies with different passivation types + back contact technology will definitely be adopted in the future. .

4. Prediction of the development of HPBC technology line

Personal judgment is HJT+IBC, for three reasons:

First, in March 2022, LONGi released a new world record of 25.40% conversion efficiency of indium-free HJT cells, while the photoelectric conversion efficiency record of indium-containing cells released by LONGi was 26.50%, and the conversion efficiency value of indium-free cells compared to indium-containing cells It is 1.1% lower, indicating that the indium-free TCO layer has either low light transmittance or low conductivity. But if HJT and IBC are combined, the indium-free problem is solved because TCO is not used. There is no grid line on the front of the back contact cell (IBC), no need to conduct electricity, and a common SiNx anti-reflection film can be used; the back side does not need to transmit light, only a conductive film can be deposited, and the range of optional materials is wider than TCO.

Second, due to the poor conductivity of the HJT cell emitter, the spacing between the p+ and n+ regions on the backside of an IBC cell using HJT technology is required to be lower.

Third, HJT+IBC can fully reflect the efficiency leadership of the new battery and meet the LONGi slogan of “not leading, not expanding production”. HJT+IBC can solve the indium-free problem. As long as the silver-free technology makes a breakthrough, the HJT+IBC technology route should be the inevitable choice of LONGi.

Reference article: 1. “LONGi Green Energy Hi-MO 6 new product launch Q&A session: Zhong Baoshen & the guests 9 questions and 9 answers”

2. “The Bottleneck of Current Photovoltaic Cell Technology”

$LONGi Green Energy (SH601012)$ $Aixu (SH600732)$ $JinkoSolar (SH688223)$

There are 57 discussions on this topic in Snowball, click to view.

Snowball is an investor’s social network, and smart investors are here.

Click to download Snowball mobile client http://xueqiu.com/xz ]]>

This article is reproduced from: http://xueqiu.com/7514682568/234647225

This site is for inclusion only, and the copyright belongs to the original author.