Economics assumes that the market is rational, but panic and greed exist all the time; physics assumes that the world is a smooth surface, but friction is everywhere; then, how can the lithium battery industry chain be free of losses? !

①Skip the section from lithium raw ore to lithium concentrate, and start directly from lithium concentrate. The lithium concentrate mentioned in this article is mainly spodumene concentrate with a lithium oxide grade of 5.5-6%, which is also widely used in lithium salt factories. The type of lithium concentrate used. We often hear “8 tons to 1 ton” is this link. The yield of lithium is about 85-90%. In the past two years, Tianqi Lithium has provided OEM for China Mining Resources and Shengxin Lithium Energy. The agreed yield is 85%. Companies such as China Mining Resources, Ganfeng Lithium Industry, and Ronghui Lithium Industry in the industry can basically achieve a yield of 90+% when using 6% spodumene concentrate to make lithium carbonate. . It is a little troublesome to use the interval, and the follow-up calculation is based on the yield rate of 90% and the loss rate of 10%. This part of the lithium loss is difficult to recover, and the loss is lost.

② The theoretical unit consumption of lithium carbonate to lithium iron phosphate is 0.2343. According to the data provided by Hunan Yuneng and Funeng Technology, the actual unit consumption is 0.25, that is to say, the lithium yield in the preparation of lithium iron phosphate from lithium carbonate is 93.3%, and the loss rate 6.7%. Lithium carbonate to NCM523, and lithium hydroxide to NCM622 and 811 are relatively complicated, with loss rates of 4.48%, 9.8% and 10.2% respectively. The announcements of Rongbai Technology and Changyuan Like have disclosed this. The average loss rate is 8.16%, and on average with lithium iron phosphate, the loss rate from electric carbon/hydrogen to positive electrode material is 7.43%. This part of the loss is also difficult to recover, and the loss is lost.

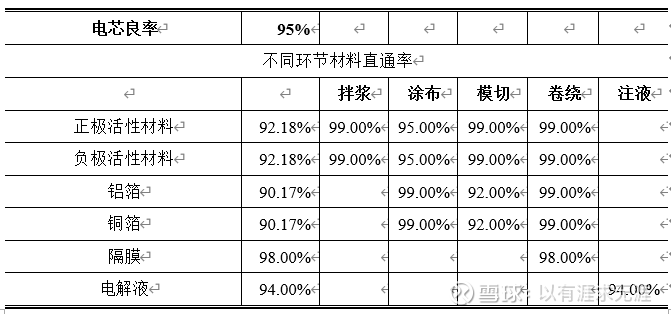

③From the positive electrode material to the battery cell, according to the test results of the Argonne laboratory, the material pass-through rate in the pole piece manufacturing process is 92.18%, and the loss rate is 7.82%. Most of this loss can be recovered, which is currently the main raw material for recovering lithium.

④ The yield rate of the final cell link is 95%, and the loss rate is 5%. If this part of the loss is a ternary battery, most of the waste in it can be recycled most of the time, because nickel-cobalt metal can help share the cost of lithium metal recycling; if it is a lithium iron phosphate battery, recycling is relatively difficult. The price of lithium carbonate is less than 300,000 yuan, and there is basically no recycling value. If a friend happens to read my previous article “Lithium carbonate price of 350,000 yuan is the basic threshold for lithium recycling of waste batteries”, don’t bother, the previous article said It is decommissioning waste, which is still very different from the inter-production waste in this article.

So far, from lithium concentrate to batteries, the loss rate of lithium resources is about 30%.

BUT!

This is just the “reasonable loss” in the public statement of the representative company of each link. Since there is a reasonable loss, there must be abnormal loss. The reason is very simple. Take the battery link as an example. Almost no battery factory builds all dedicated lines. As long as there are line changes, there will be losses. The more times of line changes, the higher the loss rate. This part of the loss is definitely not It will be recognized as “reasonable loss” by listed companies. The same is true for cathode material factories.

After the reasoning is over, let’s upload the data.

As shown in the figure, from December 2021 to September 2022, the total output of NCM batteries is 154GWh. According to the above 5% defect rate, it can be concluded that the defective batteries are 8.13GWh and the weight is 41,400 tons; also based on the above 7.82 % positive electrode loss rate, it can be concluded that 25,900 tons of pole piece waste, and the total ternary inter-production waste that should be generated is 67,400 tons.

From January to October 2022, the total amount of ternary waste recycled by SMM is 154,800 tons, of which inter-production waste accounts for 56%, so the total inter-production waste is 86,700 tons, which is significantly higher than 67,400 tons. Friends who want to talk to me about importing materials, please look at the data before you talk, thank you.

The 67,400 tons of inter-production waste is definitely not all, and no company can achieve 100% waste recycling; and the statistical samples of SMM are certainly not all, so the actual gap will only be greater.

To sum up, the loss rate of lithium resources from lithium concentrate to batteries is 30%, which is not much more .

————————————————————————————————

The reason for writing this article is because the “Global Lithium Resource Supply and Demand Balance Sheet” to be written next will be used. It is not important what the actual loss rate of the battery link (5%+7.82%) is, because according to the unified standard , Comparable caliber, I will also calculate the amount of lithium recovered from inter-production waste according to the same ratio.

$中国矿资源(SZ002738)$ $Tianqi Lithium Industry(SZ002466)$ $Ganfeng Lithium Industry(SZ002460)$ #白矿矿# #修元电竞# #ValueInvestmentRoad# @雪球创作者中心@今日论坛

There are 12 discussions on this topic in Xueqiu, click to view.

Snowball is an investor social network where smart investors are all here.

Click to download Xueqiu mobile client http://xueqiu.com/xz ]]>

This article is transferred from: http://xueqiu.com/1997338874/237623944

This site is only for collection, and the copyright belongs to the original author.