Some time ago, the ideal L9 air suspension exploded. I wrote an article that mentioned:

“…Ideal to use one’s own power to try to give the public the view of popular science in the industry of “durability of air suspension is no longer a problem, including the later developed Chinese domestic air suspension”, and bring the brakes back to before liberation. . . . …”

First, the definition of air suspension:

Automobile suspension system is a general term for the force transmission connection device between the frame and the axle, or between the frame and the wheel. Its core function is to absorb the impact force transmitted from the road to the frame or body and reduce the vibration caused by the impact force. , thereby ensuring the smoothness and handling stability of the car.

The suspension system mainly consists of three major components: guiding elements, elastic elements and damping elements. The guiding elements mainly include thrust rods, guide arms, swing arms, etc. The elastic elements mainly include leaf springs, coil springs, torsion bar springs, rubber springs, Oil and gas springs and air springs, etc., the damping elements mainly include shock absorbers, steering dampers, etc.

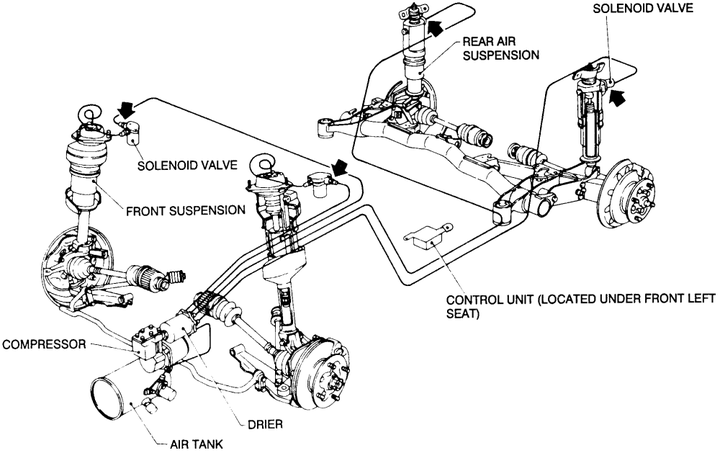

The structure of the air suspension system is mainly divided into:

Air supply part:

It is mainly composed of air compressor, dryer, height adjustment valve, exhaust valve and other structures. Under the algorithm control of the controller, the air supply system controls the flow and speed of the high-pressure air entering the air spring, so as to adjust the stiffness and telescopic length of the air spring.

Air spring:

From the definition of structure, there are actually bellows type (called sleeve type in China), membrane type and bladder type. Together with the air supply system mentioned above, the compressibility of air is used to bear the impact load.

shock absorber

At present, electronic shock absorbers are generally matched with air suspensions, with adjustable damping to improve comfort.

The air suspension has the functions of adjusting the height of the body and the suspension damping. Some types can be equipped with electronic sensors and ECU controllers. When it is detected that you have a roll or lack of support when entering the bend, the air suspension can be adjusted separately. The stiffness, damping and body height of the suspension help the car to improve the road passability and enhance the handling and stability of the car.

However, please note that the above-mentioned functions of the air suspension are only the functions that can be realized from the air suspension, which not only requires the support of hardware, but also the support of algorithms. That is to say, it does not mean that the air suspensions of all car brands have the above-mentioned technologies that can be flexibly and accurately adjusted in dynamic driving in addition to dynamically adjusting the body height and changing the damping, especially some cheap ones in recent years. system. It depends on whether the automaker emphasizes this in the publicity.

Application History of Air Suspension Systems

Air suspension was first developed in luxury or sports passenger cars, and then widely used in luxury pickups, buses and heavy-duty long-distance trucks. In recent years, it has been widely used in the development of electric vehicles.

There are different opinions about the origin of air suspension. The more recognized one is that it was first applied to an experimental vehicle named Stout-Scarab by the American Firststone Company in 1933. This is a rear-engined vehicle that uses four rubber bellows instead of traditional springs. Air is supplied by a small compressor attached to each bellows.

In fact, there is more to say here. Firststone was born out of Columbia Off-Road Vehicle Company in the United States. Columbia Off-Road Vehicle Company was a new company that developed rapidly with the development of electric vehicles in the United States after 1903. It has received a lot of investment and began to expand luxury vehicles. business, while Firststone specializes in luxury brands.

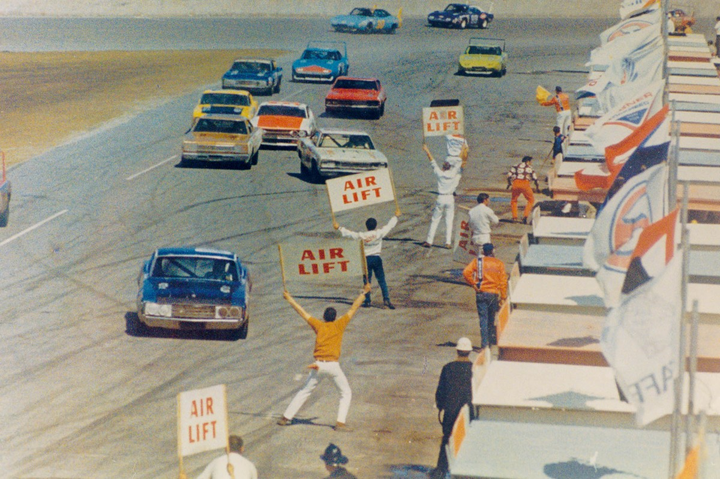

After World War II, as some air spring manufacturers introduced more reliable air spring parts, first in the late 1940s-1950s, air springs were used in racing cars, and it became a trend in American racing and modified car culture.

The real mass production application of air suspension in passenger cars started from the large-scale use of air springs by General Motors in the Cadillac brand in the late 1950s.

Although after the 1950s, the upsurge of air suspension swept the racing and modified car fields in the United States, and was mass-produced and promoted by luxury cars of Cadillac, Lincoln and other brands, but there was no real promotion in the field of passenger cars. stand up. The fundamental reasons are: 1. The system is expensive; 2. The durability is poor. When more and more car owners find their cars lying on the side of the road, realizing that the air springs have failed, the frustration caused by repairs can no longer support this expensive technology.

At the same time, for passenger cars that are not heavy, with the continuous optimization and technical iteration of the coil spring-based suspension system, especially the hydraulic shock absorber technology developed after 1933, the traditional suspension system Air springs are getting less and less cost-effective because of the dramatic improvements that racks bring in reducing bumps and improving comfort. And this system requires a lot of layout space, so the deployment of air suspension systems is not so popular gradually.

But for modified cars, heavy pickups, buses, and heavy-duty trucks, due to the weight of these vehicles and the higher demand for shock absorbers for long-term driving, the popularity of air springs for these vehicles, especially in developed countries The proportion of deployment in the model is very common. For heavy trucks and tractors in the United States and Europe, the coverage rate of air springs exceeds 90%. The proportion of high-end coaches using air springs has also reached almost 100%.

In recent years, in passenger cars, air suspension is mainly used in luxury models, such as Audi, BMW, Mercedes-Benz, Cadillac, etc., not to mention brands such as Bentley. However, Cadillac, which was the first to apply air suspension, is currently in a special situation. Since 2002, it has developed a new generation of MRC active electromagnetic induction suspension system to deploy some new models, such as the current Cadillac CT6. We will discuss this in a separate article.

The resurgence of air suspension systems with the development of electric vehicles

Air springs are used in electric vehicles, and Tesla is more representative. Tesla has been promoting its smart active air suspension since the Model S/X. Of course, at the time, the price of these two cars was not cheap, and their positioning was also an electric smart luxury car, so it was not uncommon to have an air suspension. But it’s more about this intelligence.

Tesla applied air suspension to improve aerodynamics on the one hand, lowering the suspension height to reduce air resistance and lift when driving at high speed on the highway, and to improve driving and comfort on the other hand. But the more important point is that Tesla’s electronically controlled air suspension system can give the OEM more freedom to try to control, which may be what Tesla wants to try.

Therefore, in terms of comfort and drivability of Tesla, it was not so much the advantage of the air suspension at that time, but it was more about the subsequent optimization of the algorithm to achieve better damping characteristics and autonomous response in terms of suspension height.

When the first Teslas were in Shanghai, there was a joke that there was a road in Shanghai under maintenance at that time, and iron plates were laid on the ground, which would cause bumps when driving over. Then all Teslas learned to raise the air suspension height before passing this road. However, the maintenance speed in Shanghai was very fast. Later, these iron plates were removed, but in the following half a year, all the Teslas will still be raised in height after passing through this location, and they were not canceled until the OTA upgrade.

The main reason for the application of air suspension in domestic electric vehicles is that the electrification of the new wave of startups starts from high-end, so the air suspension only equipped with luxury cars has become a good hardware gimmick. The more typical one should be the Weilai ES8.

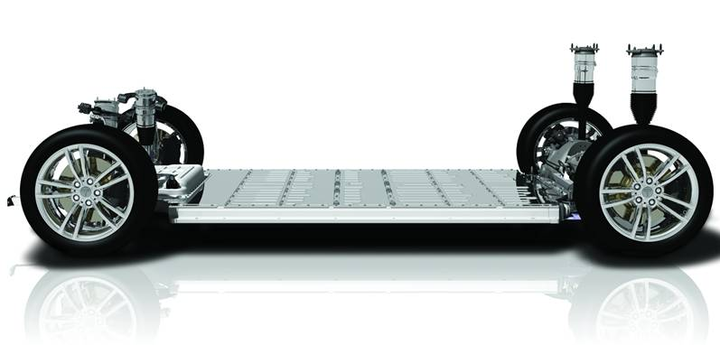

Especially in recent years, long-range models have become more and more popular. Pure electric vehicles generally use large-capacity battery packs. The battery pack is placed on the car chassis. The air suspension can better meet the requirements of pure electric vehicles for battery pack protection and vehicle chassis. New requirements for lightweight and other aspects.

Since then, the NIO ES6 has dropped the price of the air suspension to the 400,000 level, and then Geely’s Ji Krypton 001 and Dongfeng Lantu FREE have dropped even lower.

Behind this is the fact that the air suspension continues to mature from a hardware perspective, and Chinese local suppliers begin to replace the entire air suspension system with localization.

The road to localization and cost reduction of air suspension system

Currently, air suspension is not as expensive as the 50,000 class it was years ago. The price of the imported air suspension system is about 12,000-16,000 yuan, and the localized system is about 8,000-10,000 yuan.

Independent manufacturers first dismantle the entire air suspension system from a whole component system, and then gradually replace it and set prices separately. NIO has been exploring this since the beginning.

Domestic enterprises adopt a customized integrated procurement model, and in the development process, the air suspension system and the chassis system are combined and developed, and they are split into several small assemblies such as air supply units, air springs, shock absorbers and sensors. Purchasing from suppliers; automobile manufacturers develop the software of the electronic control system of the air suspension system by themselves, and undertake the functions of system integration.

At present, this development model is still relatively successful, and it is hoped to break the coverage ratio of mid-to-high-end models. With more and more localized enterprises, more and more parts are sold, which can further reduce costs.

Challenges for the future development of air suspension systems in the field of electric vehicles

First of all, the structural design of the suspended structure itself is very different.

At present, the air suspension that everyone sees on domestic cars cannot be simply equated with the air suspension of some million-level models they are targeting. There are design strengths, in addition to the differences in matching structural systems, some structures directly related to strength and durability are still quite different.

For example, the air suspension used on some high-end models of Audi RS e-tron GT, Porsche and BMW with a price of one million is a three-chamber air suspension, and its reliability, endurance strength and adjustability completely surpass that of a single air suspension. Cavity response, especially for transient conditions. There are also some high-end models of global brands that use a dual-chamber structure, which are called multi-chamber air suspension.

Therefore, the bragging limit of domestic OEMs is best not to exceed 1 million, especially if it is the strongest on the surface within 5 million in one breath, it is recommended to be cautious.

In fact, even if it is the same single-cavity suspension, the design strength, the robustness of the air supply system, and the selection of materials are all subject to the limitations of the suspension system itself, the limitations of enterprise cost control, and the limitations of safety standards and testing scope. restrictions on sex, etc. Especially on some models of the 300,000-400000000000000000000000000000000000000000000000000,000-40,000-level models, whether there will be system integration problems and problems caused by excessive compression of safety boundaries due to cost control pressure behind the abuse of air suspension, in fact, at present No one can tell.

Secondly, the air suspension is not a pure hardware, but an active control system including algorithm development.

For some simple adjustment of the high, medium and low suspension heights, as well as the damping and height adjustment of medium and high speeds, basically everyone does the same. However, the performance of the dynamic driving process and the algorithms for acceleration and braking vary widely, and it will affect the durability and safety of the air suspension.

At present, I have basically driven some models with empty suspension in China, especially the new power models. My evaluation of the chassis tuning of several domestic models currently equipped with air suspension is not high. The reason is that these models use a very soft suspension tuning throughout the ride, which I personally don’t like for performance EVs, and it’s actually not good for the drivability and durability of the car.

The most typical examples are acceleration conditions and sharp steering. For several domestic electric vehicles with air suspension, the throttle becomes a “charge boat” when the throttle is slightly larger, that is, the front of the car is raised. I am most impressed by Weilai, which should not be divided into models. Steering too.

Some time ago, the air suspension of the ideal L9 failed. Many people analyzed that it may be a problem of the air suspension control algorithm. In fact, I think it is possible. The safety of the air suspension cannot be equated with the traditional passive suspension. With the gradual standardization and serialization of the hardware system, the algorithm will be an important factor to support the air suspension drivability and safety in the future.

Finally, we come back to the question.

The development and corporate promotion of air suspension in recent years has gradually gotten rid of the hats of “easy to break” and “luxury and expensive”, and because of the “luxury” attribute of air suspension in the history, it has been regarded as a star by many companies. technology to apply. Moreover, the air suspension can effectively improve the driving experience and meet the increasingly high comfort requirements of domestic users. This makes it the choice for many manufacturers and models to pursue differentiated competitiveness after the configuration of the large-size central control screen and panoramic sunroof.

So it is true that it has been eliminated. On the contrary, it is an important period for the development of air suspension.

However, the flip side of development is abuse, and the problems that abuse can create can, in turn, limit development in slack.

In my opinion, a tune-up junk air suspension is worse and more dangerous than a tune-up junk conventional suspension. The new generation of semi-active suspension has shown a similar or even better performance than ordinary air suspension (mainly responsiveness), so the final decision to air suspension in the future is still the OEM’s system development and Algorithm development.

Ultimately, it depends on the actual drivability of the system integration. Simply looking at whether the whole vehicle is equipped with air suspension hardware is not the basis for whether a vehicle is safe, reliable, and whether it can show better comfort and drivability.

Source: Zhihu www.zhihu.com

Author: JackyQ

[Zhihu Daily] The choice of tens of millions of users, to be a big cow to share new things in the circle of friends.

click to download

There are 19 more answers to this question, see all.

Further reading:

What is the difference between air suspension and normal suspension?

Is the air suspension easy to break? How many kilometers can it last?

This article is reproduced from: http://www.zhihu.com/question/544751559/answer/2601920649?utm_campaign=rss&utm_medium=rss&utm_source=rss&utm_content=title

This site is for inclusion only, and the copyright belongs to the original author.