Text | Zhou Youhui

Editor | Peng Xiaoqiu

36氪 was informed that the industrial vision inspection company “Aocheng Intelligent” received a Pre-A round of investment of RMB 15 million, which was invested by the actual controller of an A-share listed company in his personal capacity. The funds raised in this round will be mainly used to promote the company’s development in pharmaceutical inspection. Development and implementation of new technologies.

Aocheng Intelligent was established in 2019. Its industrial visual recognition products are mainly used in the pharmaceutical production industry. At present, it has launched a series of equipment for 360-degree capsule particle inspection, a fully automatic intelligent blister inspection machine, and a visual inspection module for solid dosage bags. Obtained orders from many well-known domestic pharmaceutical companies.

According to data from the High-tech Industry Research Institute, the size of my country’s machine vision market in 2019 was 6.55 billion yuan, a year-on-year increase of 21.8%. The agency also predicted that China’s machine vision market will reach 15.56 billion yuan by 2023. From the perspective of downstream applications, in 2019, the consumer electronics, automobile manufacturing and food packaging industries accounted for 70% of the total, while the pharmaceutical field targeted by Aocheng Intelligence accounted for about 9.7%.

“There are about 5,000 pharmaceutical factories in China, and there are more than 100,000 employees in the testing station alone,” Zhang Tao, founder of Aocheng Intelligence, told 36氪 that the application ratio of automatic testing equipment in domestic pharmaceutical companies is very low, and the current penetration rate is not yet. to 1%. According to industry estimates, there are about 100,000 pharmaceutical production lines of various sizes in the country, and the market size formed by the demand for new production lines and renovation of old lines is about 10.4 billion yuan.

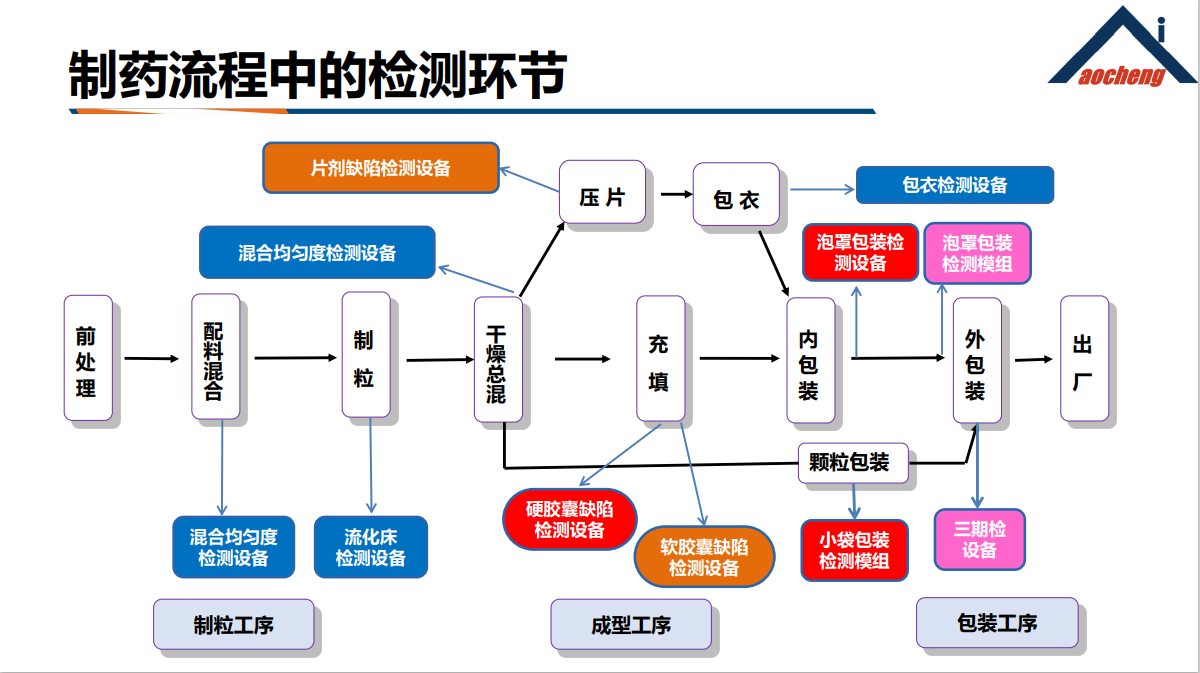

The pharmaceutical production process can be mainly divided into three processes, namely granulation, drug molding and packaging, and each process has quality inspection requirements. Because drugs are related to people’s life and health, even if there are minor defects, they will cause irreparable losses to patients after they are circulated in the market, and may even lead to medical accidents.

On the other hand, under the current long-term policy of centralized procurement with volume in public hospitals, the requirements for traceability supervision of drug quality are becoming more and more strict, and pharmaceutical companies urgently need methods or products that can improve the quality and efficiency of testing. Detection can well avoid drug contamination and missed detection and false detection. After many hours of dedicated work, the detection accuracy of the detection staff is easy to decline. At the same time, the second- and third-tier pharmaceutical factories we have investigated often face the problem of difficulty in recruiting workers. ” said Wang Chunshui, President of Aocheng Intelligence.

Figure: Testing needs in the pharmaceutical process

Specifically, Aocheng Intelligent has designed three types of industrial visual inspection equipment based on three common domestic pharmaceutical packaging – blister pills, capsules and granule pouches. Machine vision inspection equipment for tablets and softgels will also be launched in the second half of this year.

In the domestic market, most of these testing equipment are occupied by German, Japanese and Italian brands, and the price is as high as 4 million to 8 million, while the price of Aocheng smart equipment is only one-fifth to one-eighth of imported brands. Indicators can meet or exceed the industry average. Its cost-effective advantage is mainly derived from the unique design of the hardware structure and the software algorithm developed based on the needs of the pharmaceutical industry.

Taking the 360-degree capsule particle inspection series equipment as an example, Aocheng Intelligent uses the self-designed mechanical structure, uses the 360-degree rolling of the capsule on the track of the inspection equipment, and installs a prism on the inner side to collect the photos of both ends of the capsule. Only one 2D industrial camera can detect capsules with six channels, and the maximum detection speed of a single device can reach 7500 capsules/min. Imported brands mostly use five to six industrial cameras, or 3D cameras to detect capsules from multiple angles, which is expensive to manufacture.

Picture: Aocheng Intelligent 360 Degree Capsule Grain Inspection Series Equipment

At the software level, the device is based on the open source ROS robot operating system and has good scalability. Based on the team’s pharmaceutical background executives’ understanding of the industry, Aocheng Intelligent adopts a self-developed algorithm combining pattern recognition and deep learning.

The vast majority of drug defects can be identified through pattern recognition algorithms, and some rare defects can be classified and identified through deep learning algorithms. When the machine leaves the factory, it will be equipped with a pre-trained neuron network as a supplement: neuron The network learns to identify various types of drug quality defects based on thousands of sample images. This set of visual inspection algorithms is written from the bottom and does not depend on any third-party systems and algorithm platforms. It is suitable for the multi-variety, personalized and strict supervision characteristics of the pharmaceutical industry.

Three years after its establishment, its products have been initially verified by the market and have been successfully deployed in many domestic pharmaceutical group companies and listed pharmaceutical companies. In 2022, the revenue will reach tens of millions. In addition, Aocheng Intelligent also provides machine vision inspection equipment for aerospace customers, which meets aerospace customers’ requirements for rapid inspection of machine vision equipment with high precision and stability.

Talking about the future, Zhang Tao said that the production of domestic pharmaceutical companies has actually achieved the automation of the production process, but because the drugs need to be separated from the production line for manual testing between production processes, the entire production line cannot be fully automated. “Visual inspection equipment can connect various processes to complete quality inspection, and promote and help pharmaceutical companies to achieve automation and unmanned production lines.”

In terms of team, founder Zhang Tao has worked for Bank of China International and Credit Suisse Founder, and has more than 20 years of experience in investment banking and investment in the high-tech field. Co-founder Li Jiangwei has served as R&D director in international companies such as ASML, Synopsys, and Brion, and has more than 20 years of experience in the field of machine vision in Silicon Valley. President Wang Chunshui has served as a senior executive in many international companies and large state-owned enterprises such as HP, Agilent, News Corporation, Tsinghua Tongfang, and China Aerospace. Chief Operating Officer Hou Zhengxun used to be the vice president of a well-known domestic pharmaceutical equipment company, and has more than 20 years of experience in pharmaceutical equipment electromechanical R&D and factory management.

Investors in this round said that they are optimistic about the technological leadership of Aocheng Intelligence in the field of industrial machine vision and the actual deployment of many customers in the domestic pharmaceutical industry. Aocheng Intelligence will also promote the automation and unmannedization of domestic pharmaceutical production.

media coverage

36Kr ‘s new budding entrepreneurial state in the investment world

This article is reprinted from: https://readhub.cn/topic/8gSXS3SMj0A

This site is for inclusion only, and the copyright belongs to the original author.