At present, the tempo of Tesla’s Texas plant is an average of 45 seconds per car, while the tempo of the Shanghai plant has reached an average of 38 seconds per car. It seems that after long-term operation and management optimization, it is possible to realize one car in half a minute. So what are the black technologies behind it? Let’s talk about the magic of automotive one-piece die-casting manufacturing technology behind efficient production.

↑Tesla factory produces a car every 45 seconds on average

First of all, two points need to be clarified. Although Tesla has announced the patent for the integrated die-casting of the whole vehicle, at present, the integrated die-casting can only manufacture some key parts of the car body. In addition, one-piece die-casting is not the earliest casting process applied in automobile manufacturing. So let’s first look at what casting is.

what is casting

Casting is a method of casting liquid metal into a casting cavity that is suitable for the shape of the part, that is, a mold, and waiting for it to cool and solidify to obtain the part. That is, the manufacturing method of obtaining the desired shape in the process of converting metal from liquid to solid. Corresponding to it is stamping, which is a processing method that relies on presses and molds to apply external forces to metals to cause plastic deformation to obtain the desired shape. That is, a manufacturing method that converts a metal from one shape of a solid to another desired shape of a solid. The shapes that can be obtained by casting are relatively more three-dimensional and more complex.

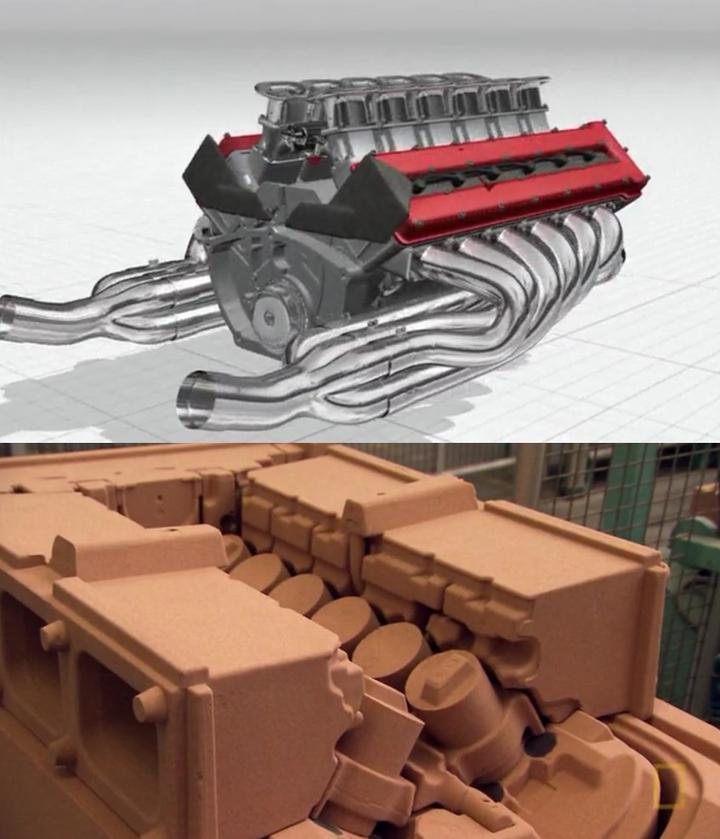

↑Ferrari V12 all-aluminum engine and sand molds for sand casting

The main application classification of casting

The current main application classification of casting in automobile manufacturing includes two categories: gravity casting and high pressure casting.

1. Gravity casting

The earliest casting process applied in automobile manufacturing was actually the manufacturing process of cast iron or cast aluminum engine block. At present, high-performance engines generally adopt aluminum alloy engine sand casting technology. Strictly speaking, engine sand casting should be called Sand Core Gravity Die Casting. To put it simply, the melted aluminum alloy needs to be poured into a mold (sand mold) made of sand, and after cooling, the sand mold outside the aluminum alloy casting needs to be removed. Therefore, the sand molds in casting are one-off, and each sand mold has slight differences. It is cumbersome to inspect, repair, pour, and remove the sand molds, and then inspect and test the obtained castings, and the unqualified ones must be returned to the furnace for remanufacturing. Therefore, engine sand casting has become synonymous with high-performance all-aluminum engines. Sand casting technology is the queen engine casting technology of all Ferrari and Maserati sports cars.

↑BMW all-aluminum engine sand casting equipment and sand molds used

The BBA also generally adopted the engine gravity die-casting technology. According to BMW’s official engine data, the aluminum alloy grade used for the engine block of the new generation of modular engines B48/B58 series is AlSiMgCu0.5, which belongs to silicon magnesium aluminum alloy, corresponding to the use of sand core gravity die-casting technology. After using the new silicon-magnesium-aluminum alloy material, BMW can further heat-treat the engine block to improve the strength of the engine block. BMW’s patented silicon-magnesium-aluminum alloy heat treatment process is through a long period of solution heat treatment above 500 degrees Celsius, and then water-cooled to close to room temperature for quenching to improve engine strength.

2. High pressure casting

↑Tesla’s integrated die-casting production process

The high-pressure casting introduced today is what we usually call die-casting. It pours molten aluminum into the pressure chamber, fills the mold cavity at high speed through its pressure, and solidifies the molten aluminum under pressure to form aluminum castings. Different from gravity casting, which is a process in which molten aluminum is injected into the mold under the gravity of the earth, die casting is cast faster and more efficient with the help of special high-pressure filling equipment.

One-piece die-casting revolutionizes automobile manufacturing

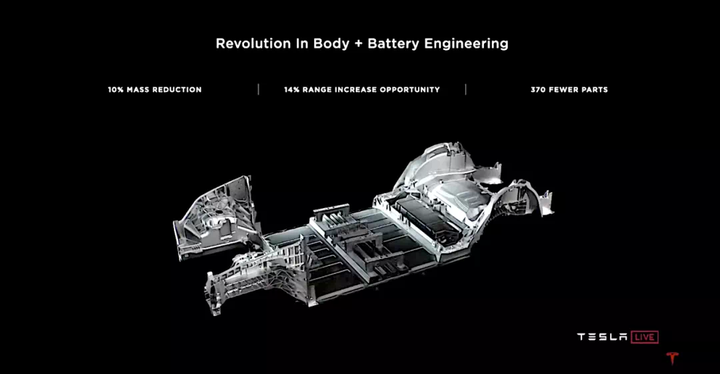

↑Tesla’s integrated die-casting brings improved production technology

One-piece die-casting is bringing huge changes to automobile manufacturing. According to the data released by Tesla, the production process improvement that one-piece die-casting will bring specifically includes reducing the weight of parts by 10%, and equivalently increasing pure electric power by 14%. The cruising range and the number of parts are reduced by 370. The greatly reduced number of components simplifies Tesla’s production steps, thereby optimizing the corresponding production and operation management efficiency.

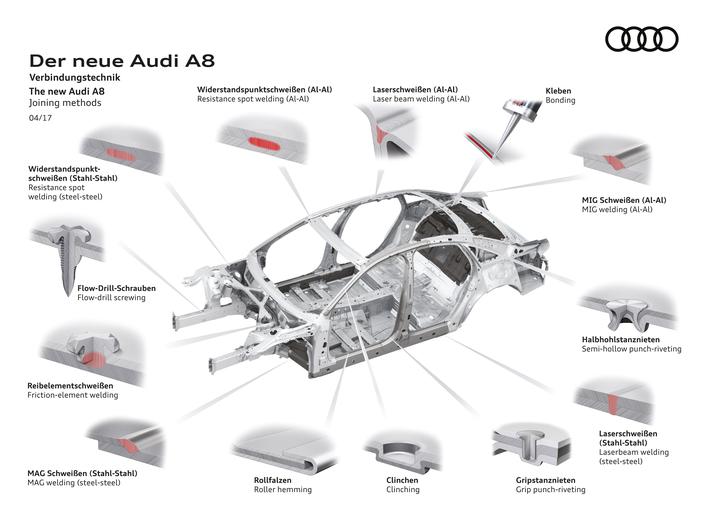

↑Audi A8 all-aluminum body joining process

The traditional body production process includes four parts: stamping, welding, painting and final assembly, while the one-piece die-casting tries to simplify the stamping + welding part. Taking the fourth-generation Audi A8 all-aluminum body joining process as an example, it includes laser welding (aluminum-aluminum), gluing (aluminum-carbon fiber), MIG gas shielded arc welding, semi-hollow self-piercing riveting, laser welding (steel -steel), rivetless pressure connection, crimping connection, MAG active gas shielded arc welding, friction stir welding, hot-melt self-tapping connection and resistance spot welding (steel-steel, aluminum-aluminum), total welding points and There are more than tens of thousands of riveting points.

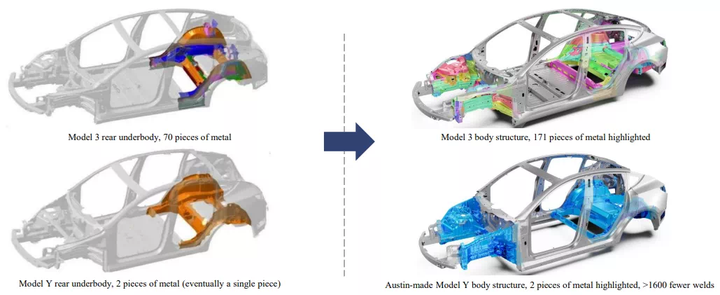

↑Tesla’s one-piece die-casting greatly reduces the number of parts and solder joints

Taking the Tesla Model 3, which adopts the traditional body manufacturing process, as a benchmark, the rear lower body of the Model Y model uses an integrated die-casting process to reduce 70 parts. The one-piece die-casting process reduces a total of 171 parts and 1600 welding points. This also reduces the total welding points of Tesla models to about 50, greatly increasing the degree of production automation and operational management efficiency.

↑Comparison of Tesla’s integrated die-casting (bottom) and traditional technology (top)

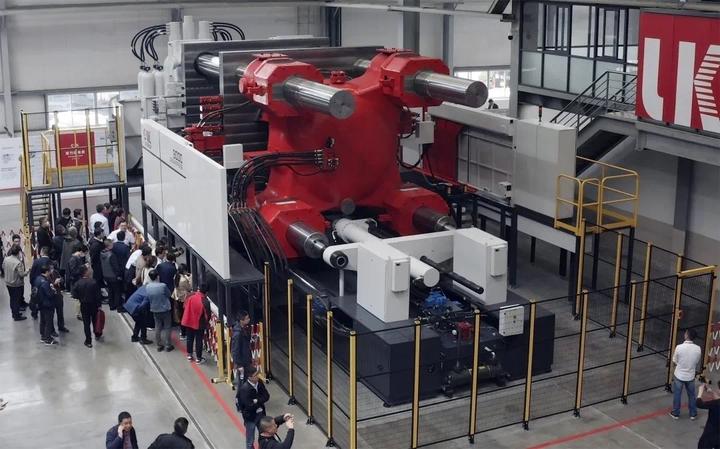

While improving production efficiency, the integrated die-casting technology has helped Tesla reduce the cost of each related component by up to 40%. This is also a direct impetus for Tesla to actively promote the further adaptation of integrated die-casting technology to more components and even complete vehicles. At the same time, some technical difficulties are still technical challenges for the popularization of integrated die-casting, that is, integrated die-casting high-pressure equipment. At present, Tesla is fully upgrading the 6,000-ton and 9,000-ton Giga Press integrated die-casting machines from LK Technology, which are the technical key to realizing a car in half a minute.

↑Tesla Giga Press integrated die-casting machine

To sum up, the current main application classification of casting in automobile manufacturing includes two categories: gravity casting and high pressure casting. The industry is expanding from high-performance aluminum alloy engine gravity casting to body-integrated die-casting. One-piece die casting has brought great changes to automobile manufacturing. Compared with the traditional body manufacturing process, the one-piece die-casting will reduce the weight of parts, reduce the number of parts and welding points, thereby optimizing the corresponding production and operation management efficiency. Integrated die-casting high-pressure equipment is still a technical challenge for the popularization of integrated die-casting.

Source: Zhihu www.zhihu.com

Author: Hot Pen Little Star

[Zhihu Daily] The choice of tens of millions of users, to be a big cow to share new things in the circle of friends.

click to download

There are 19 answers to this question, see all.

Further reading:

What is the role of integral die casting in automobile manufacturing?

What is the prospect of die casting stamping casting?

This article is reproduced from: http://www.zhihu.com/question/575505637/answer/2835617226?utm_campaign=rss&utm_medium=rss&utm_source=rss&utm_content=title

This site is only for collection, and the copyright belongs to the original author.