As a stamping process engineer, plus my previous work experience as a parts supplier, I have a relatively deep understanding of this topic. Let me analyze for you from a single stamping part, why the more cars are made, the cheaper they are.

Under normal circumstances, automobile OEMs will directly purchase small stamping parts or sub-assemblies from parts suppliers. Here we take stamping single parts as a case to understand the composition of a quotation from suppliers to automobile OEMs.

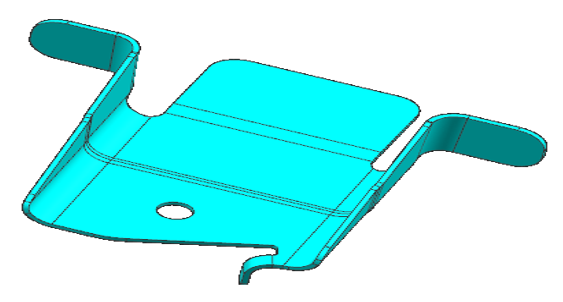

The component supplier gets the quotation demand from the automobile OEM, such as a simple fuel pump installation bracket, the tooling cost is allocated to 50,000 units, and the estimated annual output is 60,000 units . The products are as follows:

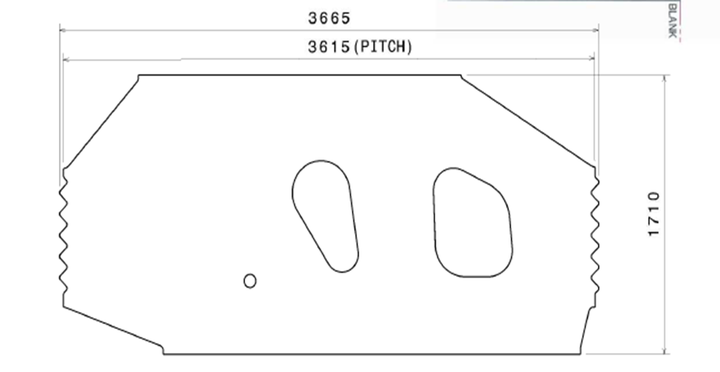

1. After getting the digital model of the part, the parts supplier will analyze the parts through software to calculate the sheet metal of most sizes, so as to calculate the weight of the material, and then calculate the zero according to the quotation of the corresponding steel model of the steel factory. The material cost of the part. For example, the material of the fuel pump mounting bracket above is 340/590DP, and the final material cost is 0.5 yuan after excluding the amount that can be sold for waste.

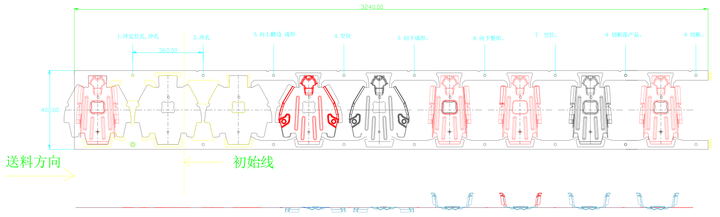

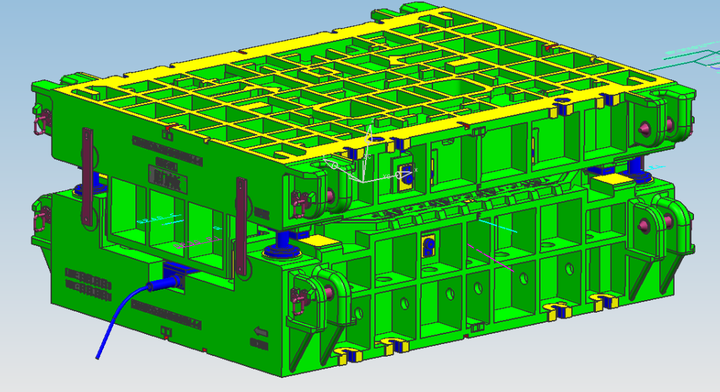

2. Then, based on the size of the part sheet, part shape, material model, and delivery method, estimate the mold size, weight, material, and whether there is a special mechanism, the size and weight of the inspection tool, etc. (if it is an assembly, there will be welding The cost of fixture tooling). For example, the tooling cost of the above fuel pump mounting bracket is 110,000 molds, the inspection tool cost is 6,000, and the tooling cost allocated to a single part is 2.34 yuan.

3. At the same time, match the appropriate stamping machine model, machine quantity and delivery method according to the size of the mold and pressure requirements. Here you can get the processing fee required for this part, and the supplier will quote according to the tonnage of the stamping machine. The above fuel pump mounting bracket is matched to the PRG 315T stamping machine, and then the delivery method is one out of two (meaning that one stamping can get two parts), and the final stamping processing fee is 0.38 yuan.

4. The supplier will also calculate the internal circulation of the product, as well as the cost of finished product transportation and packaging containers. The quantity and size of the packaging containers need to be calculated based on the estimated annual sales volume based on the size of the product. Because the single product of the above fuel pump mounting bracket is small, the cost of this part is only 0.03 yuan. (If it is an assembly or an outer panel, in order to prevent product deformation, a special product rack is required, and the number of products transported per vehicle is very small. The cost of this part is relatively large, so everyone in the automotive industry knows that many suppliers The chain is run with the car factory to reduce the cost of this part, and on the other hand, it can also reduce product quality problems caused by the transportation process, such as deformation, etc.)

5. Of course, the supplier’s quotation also needs to take into account the financial cost and management service fee . After all, the payment cycle of some OEMs can delay the supplier, so this part of the cost is taken for granted. Generally, this part of the cost The ratio is generally about 20% above (material cost + processing cost + packaging and transportation cost).

So the quotation of the above fuel pump mounting bracket = 0.5+2.34+0.38+0.03+(0.5+0.38+0.03)*0.2=3.43 yuan.

However, in the actual process, the components and products provided by the supplier may be sub-assemblies, which must include the allocation of fixtures, spot welding, nuts and studs, rubber strips, etc.

So when you see the composition of this quotation, you will find that when the actual sales volume of this model exceeds 50,000, the allocation of this tooling is gone, and the quotation of the fuel pump mounting bracket becomes = (0.5+0.38+0.03 )*1.2=1.09 yuan.

That’s right, you read that right, the cost has been greatly reduced, so if a car sells better, it will make more money in the future, and the more it is built, the cheaper it will be. Of course, the above is calculated theoretically. The calculation standard is small stamping parts. If it is a large stamping part and then apportioned to 100,000 units, there will not be such a large cost reduction. The maintenance of all kinds of tooling still needs to be carried out.

However, there are many models that fail to meet the expected sales (suppliers can only bear the risk of funds for the development of these tools), and then the models that meet the sales expectations will have a small change in two years and a major change in three years. (For OEMs, product design and tooling rectification costs will be incurred), coupled with the annual decline, in fact, the life of parts suppliers is not very easy. If the payment cycle is slow, life will be worse.

Code words are not easy, if the above sharing is useful to you, please give a thumbs up. thanks

Source: Zhihu www.zhihu.com

Author: Catcher

[Zhihu Daily] The choice of tens of millions of users, to be a big cow to share new things in the circle of friends.

click to download

There are 9 more answers to this question, see all.

Further reading:

How can I buy a car cheaper than the market?

This article is reproduced from: http://www.zhihu.com/question/574804072/answer/2837757378?utm_campaign=rss&utm_medium=rss&utm_source=rss&utm_content=title

This site is only for collection, and the copyright belongs to the original author.